Hybrid systems present a potential solution for addressing the increasingly complex nature of geothermal projects. Multi-utility buildings and 5th-generation district heating projects often have very high heating and cooling demands, which place significant importance on the design of the geothermal borefield. In the first article in this series on the design of hybrid (geothermal) systems, we focussed on the question ‘what are hybrid systems’ and how this relates to the topic of ‘geothermal potential’. This second article will teach you about two different methodologies on how to size such an hybrid system.

!Hinweis

This article builds further on the topics developed in part 1 of this series. If you have not read the first article, you can check it out hier.

Why opt for a hybrid system?

As we saw in the first part, hybrid systems combine multiple technologies to meet the buildings heating and cooling demand. In geothermal engineering, this can include various combinations such as ground source heat pumps (GSHP) with air source heat pumps (ASHP), GSHP with solar thermal collectors, or GSHP with ASHP and dry coolers. The choice of technologies depends on the specific building.

There are different reasons why one would opt for a hybrid system:

- To minimize or optimise the investment cost.

- To achieve a more robust and durable design.

Different technologies have different strengths. Geothermal borefields typically offer high operational efficiency, resulting in lower operational costs. However, borefields are often the most expensive part of the system, so avoiding oversizing is crucial. In contrast, other technologies, like ASHPs, may have lower investment costs but less operational efficiency. A hybrid design enables you to size each system component to leverage the strengths of all technologies.

The challenge: designing a hybrid system

The previous article introduced the main design challenges when it comes to hybrid systems: “If I have x boreholes, what geothermal share can I achieve?” This question was related to the concept of geothermal potential. In general, there were two extreme cases to the answer above:

- You size your borefield in such a way that there is no potential for power

(but there remains a potential for energy). - You size your borefield so that there remains no geothermal potential at all.

The first option, as we discussed last time, will give us a system with zero oversizing and hence the lowest investment cost. The second system on the other hand, will have a higher investment cost (due to a higher total installed capacity), but will have a lower operational cost. Before we can relate to any economic questions, we have to understand how a borefield can be designed so it has either no potential for power or no geothermal potential at all. This will respectively be explained in this article in respectively the methodology ‘optimise for maximum geothermal power’ and ‘optimise for maximum geothermal energy’, each explained below.

Optimise for power

When you choose to optimise for power, your design objective is

To maximise the power you can (during cooling) inject in or (during heating) extract from the ground at all times

Optimising with this objective ensures that if we install x kW of geothermal heating or cooling, we can be confident that our borefield will deliver that x kW in every your of our simulation period (provided that our load assumptions are accurate). We therefore know that if we have a building demand of 100 kW and we install x kW of geothermal power, our hybrid system can be design to deliver us (100-x) kW, since are geothermal system is designed to give us this x kW.

Methodology

The methodology that sizes this system, is the following:

- Start with an hourly heating and cooling demand profile and a fixed borefield design.

- Calculate the hourly temperature profile as if 100% of the building demand were placed on the borefield.

- You check if

- The minimum average fluid temperature falls below a certain threshold. If it does, the extraction power is too high, so reduce the peak heating power by x%. If the minimum average fluid temperature is above the threshold, the borefield can handle the extraction, and the peak heating power can remain unchanged.

- The maximum average fluid temperature exceeds a certain threshold. If it does, the injection power is too high, so reduce the peak cooling power by x%. If the maximum average fluid temperature is below the threshold, the borefield can handle the injection, and no changes are necessary.

- If both temperatures from step (3) are within the limits, the geothermal and hybrid load is determined, and you can proceed to step (7). If not, continue to step (5).

- Recalculate the hourly load for the borefield using the new maximum peak powers for heating and cooling determined in step (3). Redirect the power or energy that cannot be handled by the borefield to the hybrid technologies.

- Recalculate the hourly temperature profile and return to step (3).

- Done

Example

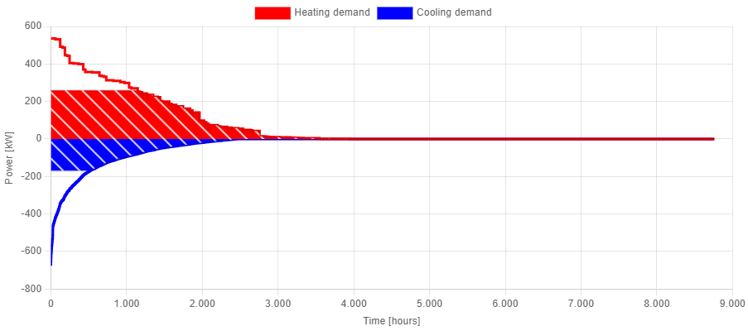

When applying this methodology to a larger multi-utility building with peak demands of 536 kW for heating and 676 kW for cooling, supported by 80 boreholes, we arrive at the figures shown below.

!Hinweis

This article focuses on the methodology itself. In a follow-up article, we will delve deeper into the practical design of hybrid systems using GHEtool Cloud.

The load-duration curve above illustrates the heating and cooling demands of the building, with the hatched area representing the portion of the load that can be met geothermally. In this case, we can install 259 kW of geothermal heating power and 169 kW of geothermal cooling power, ensuring these capacities can consistently be exchanged with the ground. The remaining power and energy requirements must be supplied by hybrid technologies.

!Hinweis

This methodology does not specify the configuration of the hybrid technology, as that falls outside the scope of geothermal design. This flexibility makes the optimisation method adaptable to various scenarios.

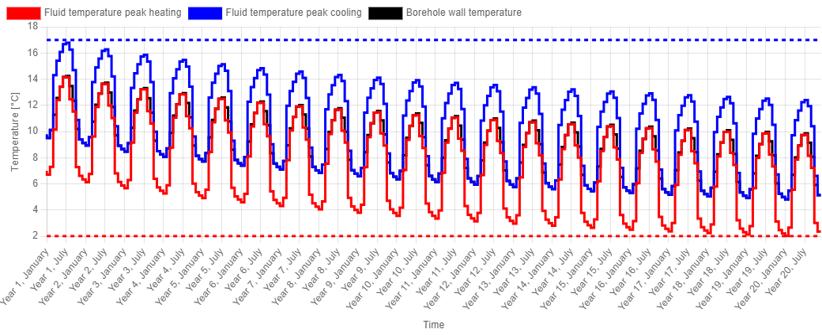

Examining the temperature profile above, we observe that both the minimum and maximum average fluid temperature limits are reached. This indicates that installing additional power for either heating or cooling would exceed these thresholds. Thus, the resulting profile is indeed optimised for maximum power. For further details on temperature profiles, refer to our article on interpreting temperature profiles.

It is worth noting, however, that some geothermal potential remains unused with this optimisation approach. In the later years of operation, there is significant capacity for additional heat injection (i.e., cooling), while in the early years, the borefield could manage a higher heating load. Addressing this unused potential would involve optimising for energy, which will be discussed in the next section.

Optimise for energy

When you choose to optimise for energy, your design objective is:

To maximise the energy that you can (during cooling) inject in or (during heating) extract from the ground during the whole simulation period

Optimising with this objective provides a system where, if we install x kW of geothermal heating or cooling capacity, we can ensure that the borefield delivers the maximum possible amount of heating or cooling energy over time. However, this approach does not guarantee that the borefield will consistently supply x kW of power at all times. Therefore, if you have a building with 100 kW of peak power demand and you install x kW of geothermal power, your hybrid system should be larger than (100-x) kW, since we cannot be sure that we can get this geothermal power in every year, so we need to compensate for that by installing more hybrid power.

Methodology

The methodology for optimising for energy differs from the approach used to optimise for power and proceeds as follows:

- Start with an hourly heating and cooling demand profile and a fixed borefield design.

- Convert the hourly load into a monthly load, maintaining the same energy demand and peak powers for each month.

!Hinweis

While it is theoretically possible to apply this method directly with hourly resolution, it would require several hours to compute without significantly improving accuracy. - Iterate through each month (i) of the simulation period, performing the following steps:

- Calculate the monthly temperature profile

- Check whether:

- The minimum average fluid temperature for month (i) is below the minimum threshold. If it is, the extraction power is too high, so reduce the peak heating power by x%, but only for month (i). If the temperature is above the threshold, the borefield can handle the extraction, so the peak heating power remains unchanged for month (i).

- The maximum average fluid temperature for month (i) is above the maximum threshold. If it is, the injection power is too high, so reduce the peak cooling power by x%, but only for month (i). If the temperature is below the threshold, the borefield can handle the injection, so no adjustment is necessary for month (i).

- If all fluid temperatures are within the limits, determine the peak power and corresponding energy that the borefield can deliver for month (i). The remaining power and energy must be supplied by the hybrid solution. Proceed to step (3.5).

- If fluid temperatures are outside the limits, adjust the hourly load to align with the new peak powers determined in step (3.2). Reconvert the hourly load to a monthly load and return to step (3.1).

- Once all temperatures for month (i) are acceptable, move to month (i+1).

- Done

Example

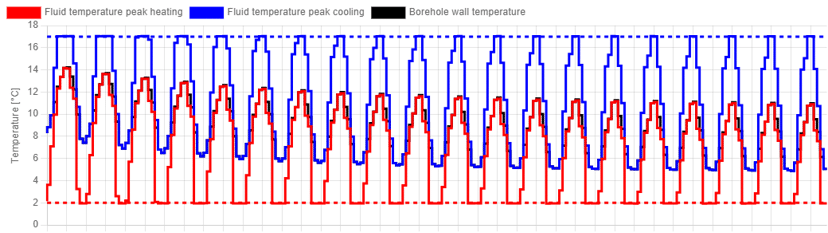

If we consider the same project with 80 boreholes, we can increase the installed geothermal capacity to 536 kW for heating and 388 kW for cooling. This allows us to extract more heat from the ground during the early years (for heating) and inject more heat into the ground during later years (for cooling). In doing so, we maximise the total energy exchanged with the borefield.

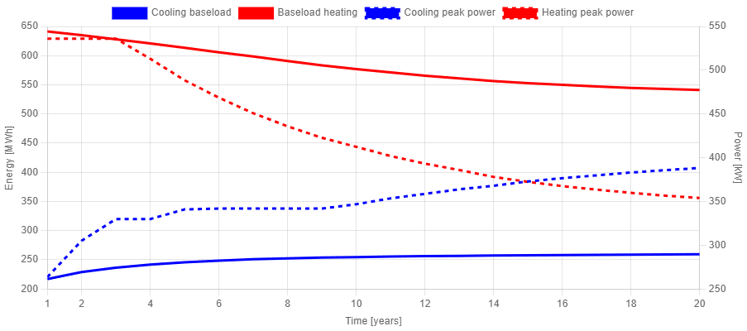

However, unlike the previous hybrid system, we cannot guarantee that the borefield will always deliver 536 kW for heating and 388 kW for cooling. The figure below illustrates the distribution of heating and cooling loads over time. As shown, due to the system’s imbalance, both the baseload heating and peak heating power decrease over the borefields lifetime, while the share of cooling increases.

!Hinweis

There is a key difference between the designs optimised for power and those optimised for energy. In a system optimised for power, the yearly geothermal yield remains constant because the peak power is always met. Conversely, in a system optimised for energy, the geothermal yield evolves over the course of the simulation period, reflecting variations in the heating and cooling loads.

Comparison

The circle diagrams below illustrate the same concept. In the results on the left, representing the hybrid system designed with ‘optimised for power’, approximately 75–80% of the building’s demand is met by the borefield. In contrast, the diagram on the right, representing the hybrid system designed with the ‘optimise for maximum energy’, achieves up to a 95% share of geothermal energy over the entire simulation period, thanks to the higher installed peak power. This means that our hybrid system, design with a borefield optimised for energy, will probably have a lower operational cost, due to the higher share of the geothermal energy. On the other hand, as you can see, the total power installed in this case, is way bigger (the geothermal heat pump is 536 kW and it is only 2/3 of the total installed power). This will give rise to a higher investment cost in comparison to a borefield optimised for power.

Fazit

The article above outlined the theoretical foundation the design methodology for a hybrid system. A distinction was made between hybrid systems which have a borefield that is designed so it has no potential for power and hybrid systems which have a borefield sized so it has no geothermal potential at all. The design methodologies were respectively called ‘optimise for power’ and ‘optimise for energy’.

In the next part, we will explore how to apply these design methodologies in GHEtool Cloud for a specific project. Additionally, we will delve deeper into strategies for limiting geothermal peak power to prevent system oversizing.

Literaturverzeichnis

- Sehen Sie sich unsere Videoerklärung auf unserer YouTube-Seite an, indem Sie klicken hier.