Hybrid systems, and especially hybrid geothermal systems, are a proven and efficient way to sustainably heat and cool buildings. By combining intelligent borefield design with other technologies (such as an air-to-water heat pump or solar thermal collectors), you can achieve optimal performance for your total HVAC system. In this article, we will build further upon the concepts of hybrid systems and geothermal potential, exploring in detail how you can use GHEtool Cloud for your next geothermal project.

!Note

This article builds upon the topics introduced in part 1 and part 2 of this series, where various important concepts were discussed. If you have not yet read those articles, you can find them here: article 1 und article 2.

The case-study: a multi-utility building

Hybrid geothermal systems are particularly beneficial for large buildings (or clusters of buildings) with a high heating or cooling demand. The case study discussed in this article is based on a real-life project, which has a heating demand of 536 kW and a cooling demand of 676 kW, with an annual energy demand of 643 MWh and 267 MWh, respectively. If we were to use a 100% geothermal solution for this building, we would need a borefield of 130 boreholes; however, space constraints allow for only 90 boreholes. Consequently, a hybrid system is required.

If you would like to follow along and design the hybrid system yourself, the design parameters are provided below. Any values not explicitly mentioned are assumed to be the default values within GHEtool Cloud:

- Hourly building load (download hier)

!Caution

This methodology requires an hourly load profile for your building demand. At present, it is not yet possible to conduct the same analysis using monthly load profiles.

- General:

- Simulation period: 40 years

- Ground:

- Thermal conductivity: 1.9 W/(mK)

- Location: ‘BEL-Antwerpen’

- Borefield:

- Spacing: 6 m (in length and width)

- Buried depth: 0.7 m

- Borehole depth (w.r.t. buried depth): 150 m

- Thermal demand:

- SCOP: 5 / SEER: 20 (passive/free cooling)

!Caution

This article uses the ‘optimise load profile’ feature, which is only available for users with an optimisation licence. If you wish to use this method, you can either upgrade a specific project to this bundle or upgrade your entire licence in the admin dashboard of your account. For more information, please refer to our pricing page.

Design your hybrid system

Designing a hybrid geothermal system is always an iterative process. You must continually adjust your design until you achieve an optimal system for your situation, whether based on economic parameters or the need for a backup installation. For this project, the following scenarios were calculated using GHEtool Cloud and will be briefly discussed below.

Optimise power – 10×9 borefield

Initially, all information was entered into GHEtool Cloud to design the hybrid system for maximum power. This approach is recommended because:

- It is the fastest method.

- It provides an initial estimate of the geothermal power potential without oversizing the total installed power.

The resulting system achieved a geothermal energy share of 78% for both heating and cooling demands, with installed capacities of 178 kW and 247 kW, representing 46% of the total heating power and 26% of the cooling peak demand.

Optimise power – 9×9 borefield

The next step is typically to reduce your borefield size (saving on investment costs) and assess the effect on your geothermal share. For this project, we reduced the size by 9 boreholes to create a borefield with dimensions of 9×9. Once again, optimising for power resulted in a hybrid system with a geothermal energy share of 74% and 73% for 160 kW and 224 kW installed, respectively. The resulting share is only slightly lower than in our previous scenario (we lose only about 4%), whereas our borefield size has been reduced by 10%! From an economic perspective, this presents an interesting trade-off.

Optimise power – 9×8 borefield

When we reduce our borefield size even further, we observe a further decline in geothermal energy share—68% and 70% for heating and cooling, respectively. Although we have now removed only 9 boreholes (compared to 10 in the previous scenario), our share of geothermal energy for this project decreases significantly. This can be explained by the load-duration curve shown below.

As you can see, our installed heating power of 202 kW already has a significant number of full load hours. Therefore, reducing the borefield size (which results in a decrease in geothermal heating power) has an immediate impact on the geothermal energy share.

Conclusion optimise power

For this project—although this is highly dependent on your specific case—the hybrid system with a borefield of 9×9 appears to be ideal for our situation, offering a good balance between borefield size and geothermal energy share. However, as you can see from the resulting temperature profile for this scenario, there is still considerable untapped energy potential in both heating and cooling. We can further exploit this potential in our future scenarios.

Optimise energy – 9×9 borefield

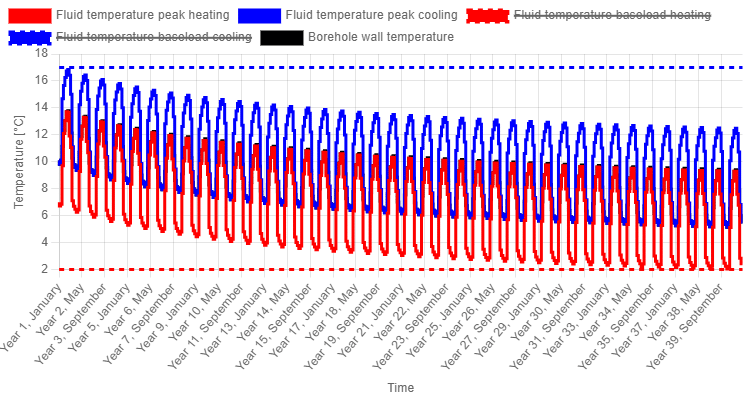

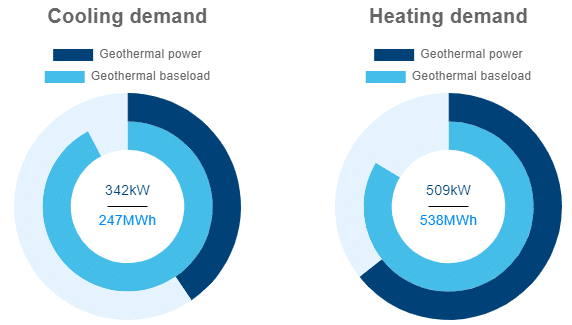

After exploring various hybrid systems using the ‘optimise load profile – power’ option, you can further refine your profile by optimising for energy. When doing so, the algorithm (as explained in our previous article here) will install additional heating and cooling capacity to maximise the geothermal energy share over the entire simulation period. This results in a geothermal energy share of 84% and 92% for heating and cooling, respectively, with an installed capacity of 509 kW and 342 kW.

As you can see from the temperature profile below, this additional installed capacity fully taps into the remaining geothermal energy potential, ensuring that the borefield reaches its temperature limits in every year of its operational period. However, with this hybrid system design, there is a significant oversizing of the total installed capacity, as we now have 790 kW installed for heating (instead of the required 536 kW) and 845 kW for cooling (instead of the required 676 kW). It is therefore considered good practice to investigate whether limiting the installed geothermal capacity would have a significant impact on the overall system performance.

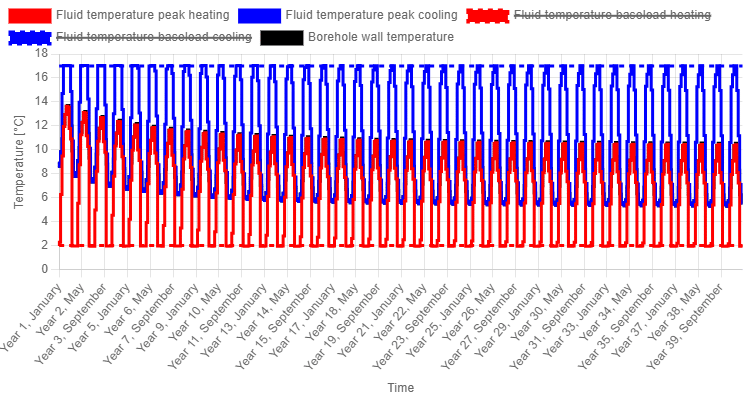

Optimise energy – 9×9 borefield (350 kW)

If we reduce the installed geothermal capacity for heating to 350 kW (assuming passive cooling for the cooling system, where oversizing the passive heat exchanger is not a major concern), our temperature profile below shows that there is still some geothermal energy potential available during the first four years of operation. This can also be observed in the geothermal contribution graph.

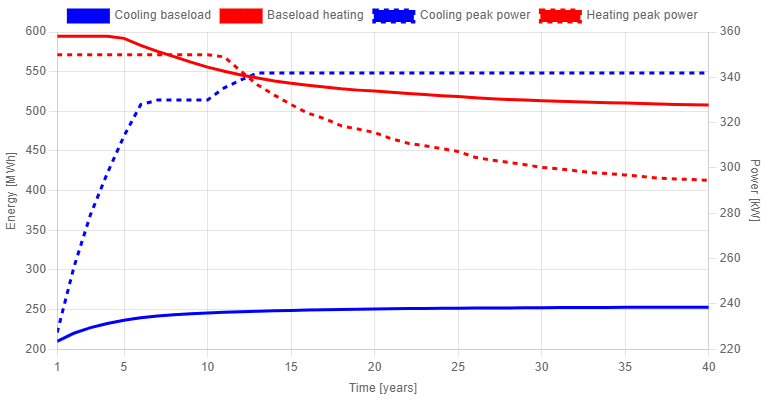

As shown in the figure below, the geothermal heating capacity provided by the borefield remains constant for the first four years of the simulation period, after which it declines due to the system imbalance. As always, the capacity decreases more rapidly than the baseload energy, since the highest peak loads account for only a small percentage of the total energy demand, as can be clearly seen in the load duration curves.

Finally, when we examine the geothermal share over the entire simulation period, we achieve almost the same geothermal energy share as before (i.e. 83.4% instead of 83.6% for heating and 92.2% instead of 92.3% in cooling), but with 150 kW less installed geothermal capacity for heating. Therefore, this system will always be more cost-effective to install without compromising performance.

Optimise energy – 9×9 borefield (250 kW)

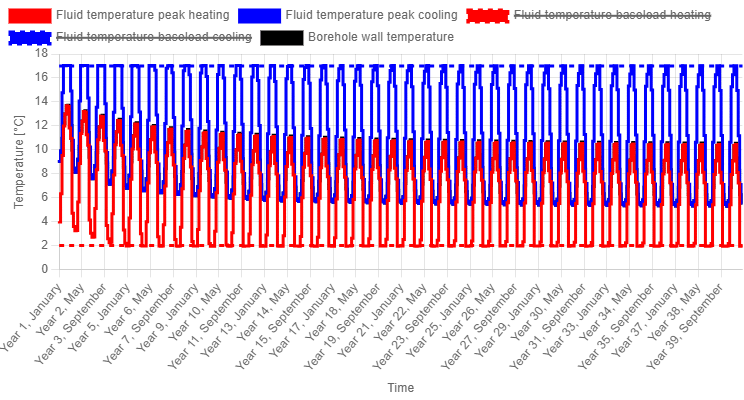

As a final step in the optimisation process, we explored whether further reducing the installed capacity of the ground source heat pump to 250 kW would be beneficial. Looking at the temperature profile below, we can see that there is now a relatively high remaining energy potential. This is somewhat expected, as the algorithm originally suggested 509 kW to achieve the maximum energy share, whereas we are now working with only 250 kW.

If we examine the geothermal contribution graph, we notice something very interesting. It appears that the 250 kW installed capacity can be delivered consistently throughout the simulation period, just as with the earlier optimisation for power mentioned above. However, when optimising for power, we could only achieve 224 kW, whereas now we have 250 kW. This difference is due to the reduced imbalance, as we inject significantly more heat into the ground thanks to the higher cooling share (90% compared to 74%). This reduces the average ground imbalance from -166 MWh/year to -148 MWh/year, creating more opportunities for heating.

Finally, if we look at the geothermal share, we achieve 78% in heating and 90% in cooling, with no oversizing of the installed heating capacity. This is a very interesting result, as by installing more passive cooling— which has a relatively low cost— we can increase the geothermal share from 73% to 78% for heating and from 74% to 90% for cooling, all while using the same borefield.

Conclusion

There is no definitive answer to which hybrid geothermal system is the best, as it largely depends on a variety of factors. Therefore, it is always beneficial to compare different scenarios side by side. In the article above, we provided an example where we began by optimising for power, gradually reducing the borefield size until we found an optimal balance between borefield size and geothermal share. By then optimising for energy, we further enhanced our initial hybrid system design, increasing the geothermal share. GHEtool Cloud is perfectly suited to assist you in designing such complex projects.

In the next section, we will evaluate the economic aspects of these different designs and demonstrate how you can determine the most suitable option for your specific project.