Designing hybrid systems is not trivial, as it requires finding the right balance between installed geothermal power, system imbalance, and overall performance. Within GHEtool, there were already two optimisation methods available for designing such systems: optimise for power and optimise for energy. Today, we’re introducing a third option to help you design even better hybrid systems!

!Note

This article builds on the concepts introduced earlier in this series. If you are not familiar with hybrid systems, please consider reading this article first.

Context

In our first article about hybrid systems, we introduced the concept of geothermal potential. (If you haven’t read that article, you can find it here.)

We identified three main types of geothermal borefields:

- Borefields with potential for power

- Borefields with potential for energy

- Borefields with no geothermal potential

Each of these hybrid system designs has its own advantages and disadvantages. A borefield with no potential left for power was considered to be optimised for power. This results in a hybrid system that is most optimal in terms of investment cost, as there is no oversizing of the installed power. The downside is that not all geothermal energy potential is used.

When a borefield is optimised for energy, there is no geothermal potential left in terms of either power or energy. This provides the hybrid system with the highest efficiency, but it comes at a higher investment cost, as more geothermal power must be installed.

The issue with both optimisation methods is that they are based on a specific time frame (e.g. 20 or 40 years), which is, to a certain extent, an arbitrary choice. The question then becomes: what happens after this period?

Optimise for balance

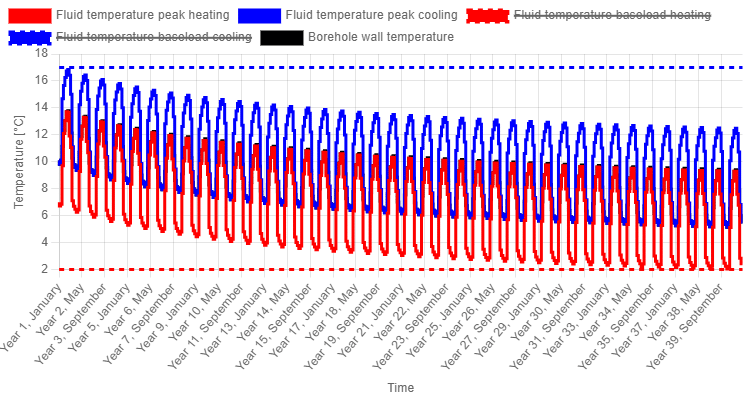

Below are two temperature profiles from hybrid geothermal systems that were optimised respectively for power and for energy. As you can clearly see, both systems show a negative imbalance, where the borefield is dominated by extraction. So what happens after the 20-year simulation period? The borefield continues to cool down…

This observation led to the development of a third type of optimisation: optimising for balance, where the goal is to design your borefield so that the ground temperature remains balanced over time. In this way, regardless of the time horizon, your system stays within temperature limits.

Objective

When you choose to optimise for balance, your design objective is

To maximise the power you can (during cooling) inject in or (during heating) extract from the ground at all times and keep the ground balanced.

This objective is very similar to the method used for optimising for power, with one key difference: an additional ground balance criterion is introduced. (If you haven’t read the article on hybrid optimisation methodologies, you can find it here.)

Optimising with this objective ensures that if you install x kW of geothermal heating or cooling capacity, you can be confident the borefield will reliably deliver x kW throughout the entire simulation period, as long as the assumed load profiles remain valid—without long-term thermal drift.

Methodology

The design methodology that sizes this system for balance, is hence also rather similar to the methodology for optimising for power:

- Start with an hourly heating and cooling demand profile and a fixed borefield design.

- Calculate the hourly temperature profile as if 100% of the building demand were placed on the borefield.

- You check if

- The minimum average fluid temperature falls below a certain threshold or there is more than $\alpha$% of imbalance. If it does, the extraction power is too high, so reduce the peak heating power by x%. If the minimum average fluid temperature is above the threshold, the borefield can handle the extraction, and the peak heating power can remain unchanged.

- The maximum average fluid temperature exceeds a certain threshold or there is more than $\alpha$% of imbalance. If it does, the injection power is too high, so reduce the peak cooling power by x%. If the maximum average fluid temperature is below the threshold, the borefield can handle the injection, and no changes are necessary.

- If both temperatures from step (3) are within the limits and the imbalance is less than $\alpha$%, the geothermal and hybrid load is determined, and you can proceed to step (7). If not, continue to step (5).

- Recalculate the hourly load for the borefield using the new maximum peak powers for heating and cooling determined in step (3). Redirect the power or energy that cannot be handled by the borefield to the hybrid technologies.

- Recalculate the hourly temperature profile and return to step (3).

- Done

Here, again, another criteria was introduced to take into account the imbalance.

!Note

The imbalance percentage is defined as: the yearly imbalance divided by the maximum of the yearly heat injection or extraction.!Note

Since this optimisation is an extension of the “optimise for power” method, the latter can be seen as a special case of the balance method. If you allow for 100% imbalance (i.e. remove the balance criterion), the method reduces to the “optimise for power” approach. This will also be demonstrated in the case study that follows.

Case study

When we refer back to our case study for the multi-utility building, we found that when optimising the system for power, a 9×9 borefield allows for 224 kW of geothermal heating and 159 kW of geothermal cooling, which corresponds to 73% and 74% of the building’s heating and cooling demand respectively. When optimising for energy, the geothermal share could even increase to 84% for heating and 92% for cooling, although this comes with a significantly higher investment cost.

Below, the hybrid system for the multi-utility building is designed using an acceptable imbalance of 5%, 25%, and 100%.

5% imbalance

As shown in the figure below, the system has only a slight imbalance (around 10 MWh/year), compared to the 167 MWh/year imbalance seen when optimising for power. This makes the system extremely robust for the future. However, there is still a considerable amount of geothermal potential for power left unused: only 107 kW of heating power and 150 kW of cooling power are installed. As a result, the geothermal share drops to 41% for heating and 72% for cooling, which is significantly lower than the 73% and 74% achieved when optimising for power.

!Caution

Although the theoretical limit for acceptable imbalance is 1%, it is recommended to optimise for at least 5% for computational reasons. Depending on your hourly load profile, it could be that there simply is no power for which the imbalance is below your tolerance. This is particularly likely for buildings with very high full load hours. If you notice that the optimisation process takes a long time, consider starting with a higher acceptable imbalance percentage.

25% imbalance

When allowing for 25% imbalance, the geothermal imbalance increases to 67 MWh/year (in extraction), causing the ground to cool slightly over the years. The installed geothermal power rises to 145 kW for heating and 153 kW for cooling, resulting in a geothermal share of 53% and 73%, respectively. This marks a significant improvement compared to the previous case with 5% imbalance and illustrates the flexibility of the optimisation for balance methodology.

100% imbalance

Lastly, as previously mentioned, optimising with an acceptable imbalance of 100% yields the same result as optimising for power. The resulting temperature profile is shown below for completeness.

Conclusion

The optimise for balance method is a valuable addition to the hybrid system design toolbox. While it typically results in the lowest geothermal share compared to other methods, it provides the most robust and future-proof design. By adjusting the acceptable imbalance percentage, you can gain a clear understanding of how much imbalance is acceptable for your system and what impact this has on the overall design.

References

- Watch our video explanation over on our YouTube page by clicking here.